This is going to be a bit of an ongoing post as i have started to prepare to fit the Omex 600 System to the Opel Manta and thought it would be good to update this post as i go along with diagrams, setup etc.. in case anyone else is looking to do the same thing as its quite hard to get much info.

So i bought the Omex 600 to replace the Webcon Alpha system as they no longer make or support it 🙁 so long term it would have to go at some point as it would just be too complicated to keep getting it adjusted if things change on the engine setup.

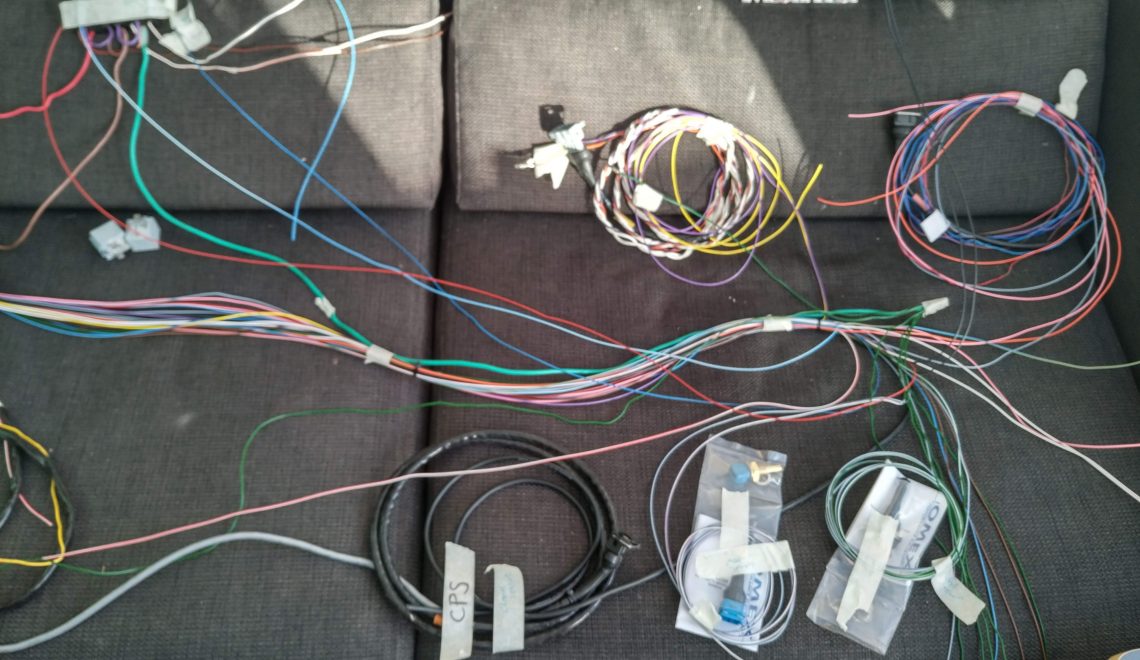

I bought the 600 ECU and bare loom as im going to use all the connectors from the Webcon loom as its quite well put together and saves money on buying all new connectors. The base loom from the Webcon has the relays and a lot of the basic wires like live and neural so i will be reusing that and adding in the Omex loom to complete a custom fit one where everything will be just where i want it so, in the long run, it will be far better.

I have unwrapped the Webcon loom and labelled all the wires and connectors and started to identify where the Omex ones go and the good thing will be with this setup i can tuck all the unused wires away inside the car as on the Webcon i had lots of wires and plugs all over the place in the engine bay that i had to tie up, so it will be neater all round.

Roughly set out the loom. The good thing with this is i can get it almost ready inside in the dry!!

Next step is to bundle both sets of wires up properly and label them so i can then fit the loom into the car and start to work out the length and best route for each one and then start wrapping the loom in place.

I will add a drawing of the relay and fuse setup soon as i found this info hard to come by.

FEB 8th

Today was a nice sunny day and dry so i had two options. Take the bike out for a run or start putting the loom in the car! Normally it would be the bike but this time the car won 🙂 I had already managed to get all the wires sorted into the right groups along with the sections of the old loom that im using so it was a case of carrying the loom to the car carefully and staring to place everything where it should go so i could start to work out the position and lengths of the various sensors etc..

i have a rough setup and now when i get another dry day i can double-check everything and start to get the loom wrapped up and work out the final lengths. I want to make sure that this time everything is just the right length with a little slack for movement and that its all out of the way of anything hot!

I have now started to wrap the loom so as soon as i get another dry day i hope to have the loom all wrapped and to start adding all the connectors and plugging things in 🙂

March 30th

The only good thing that the lockdown has provided so far is that i have more spare time to be able to work on the car 🙂 The loom is now fully wrapped and back in the car.

I have the coil to mount and a couple of connections inside for the switched feed and the rev counter and then i can attach the ECU and turn it on and see if we are all working!

its then time to sort the timing of the cam and get ready for a startup.

Soon i will be adding a diagram of the wiring setup now i have time to draw it up.